Concrete Pier System has worked for decades to come up with the highest quality pole barn kits that are made of durable materials and built to last.

Joe Timbrook started in 1981 after the original shop he built rotted in just 20 years. It wasn’t something he could continue using without a whole rebuild. Since then he has worked tirelessly to perfect the process with quality and speed. He created the Brute Force Bracket system, which gets posts out of the ground and onto a solid level platform. It’s the fastest most accurate way to build. Put your trust in CPS and let them provide you with your next pole barn kit that will last you a lifetime.

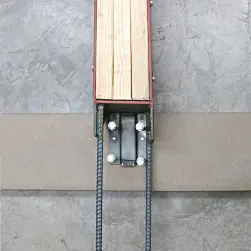

Brackets

Our standard brackets are five inches wide and are designed to accommodate three 2x6s as a post (custom sizes available). The rebar is welded to the bracket with a two inch weld making a super strong connection.

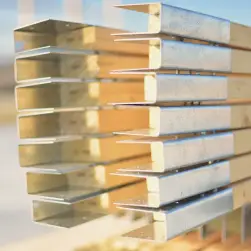

Purlin Clips

Made of galvanized steel for 2×4 rafters, purlin clips can be fastened with nails or screws (not included). You need approximately 50/1300 sq. ft. Our purlin clips make it easy to have consistent screw holes pre drilled on your roofing panels.

Belling Augers

We are the only kit that offers the option of a Jess Tools Belling Auger, for purchase or rental. This one of a kind skid steer tool is easy to operate and can complete your belled pier hole in just 10 minutes.

Concrete forms

CPS provides custom concrete forms for the top of your pier to provide a uniform above ground appearance to your columns. These forms are reusable and provide an accurate way to level the top of your pier.

Ez mount clips

The Ez-Mount clip is a small clip that is installed onto your splash boards with speed and levels at just the right height. Using a tab on the bracket, the easy mount clip ensures that the Bracket will be perfectly aligned and level.

Steel siding

CPS only uses Everlast siding and roofing steel. Everlast uses a paint system called Synergy® which is comprised of three layers. The paint Everlast uses has been tested for 50 years, and is made with US premium grade steel.

Columns

CPS Columns come precut to your design. They slot into CPS brackets to be kept free from decay. Because they are anchored firmly to a real concrete pier you can lay them flat on the ground and frame on the ground.

Trusses

CPS Pole Barn trusses are made from premium selected wood and are the best way to support your roof.

Stronger and Faster Pole Barn Design

Our system is stronger, and lasts decades longer than most systems. All the parts are designed by experienced builders for maximizing profits and competitive advantages.

Better than Perma-Column

For a building that will last decades longer, be stronger, and easier to build is it worth paying a little more? You will use less labor to assemble our kits, saving money that other kits don’t quote you.

Better than Other Pole Barn Kits

CPS is better than the cheap big box solutions which often use substandard materials, and old school methods to get you that bargain basement price.

A Company You Can Trust

CPS has been in business for decades now focusing on what they do best. Their pole barn kits are ready to take your project to the next level.